7 Power-Packed Technologies In Supply Chain

Technology! Definitely, it’s not something we can turn a deaf ear to. Every company found their varied tech fondness in respective fields. Entering 2022 and rolling the curtains of the online boom, the traditional supply chain has come to a halt. Old methods possessed bizarre ways of supply, messed up inventories, and unsatisfied customers. Making the whole of the supply chain and its management cost-efficient, the companies need a powerful combination of technologies and human resources. Working in the supply chain can involve many roles at a time like working under managers and buyers for fetching the right products, proper communication with the customers and suppliers, risk mitigation, and many more.

These channels and operations need thorough leadership of human resources and high support of technologies to make them victorious. The foundation for intelligent supply planning has gained significance as the concentration on technological improvements and shift in consumer standards has intensified. Organizations might build end-to-end logistic solutions, hasten procedures, and alleviate the risks in the supply chain.

Every role in the supply chain and E-commerce market expects automation. Here are some of the technologies and strategies binding their threads around the respective roles in this industry.

Effective information management

Knowledge management effectiveness could perhaps assist an organization in delivering its service to users undergoing operational obligations. Punctual distribution, lower inventory levels, order status, shipments and expediting, order efficiency, order thoroughness, consumer pick-up formation, forwarding opportunities and product substitution are prioritized by organizations with the support of this technology.

An ecosystem of connected devices

This characteristic of IoT has raised the caliber of how we manage supply chains in our businesses. From raw material purchases to payment security, all are operated expansively. By adopting IoT for logistics and operations, the journey to develop and set up the analytical strategies for polishing operational efficiency, product manufacturers relied arms on this tech. To read more about IoT and connected devices check out our blogs and case study.

The way organisms and environment are interconnected and create an ecosystem; likely on that route, our world of technology mentors us to understand several relationships between these wholly connected devices. Consequently, everything results in a dynamic transformation. This ecosystem; connecting IoT analytics and humans, helps the engineers to avoid delays and supply chain miscalculations, also simplifying manufacturing complexities.

Radio Frequency Identification (RFID) chips

Radio frequency identification systems, barcodes, and lasers are all important pieces of technology that may assist the company in a variety of ways. RFID chips or barcodes, for example, may be embedded in every commodity, enabling organizations to track inventory effortlessly. With automated product management, this system enables organizations with a high and dramatic increase in supply chain efficiency, thereby it helps to recognize any transaction irregularities as events arise, permitting professionals to correct inaccuracies and eliminate defects promptly. This technology also enables speedier and much more reliable traceability across the distribution network, offering comprehensive transparency and control over components.

Digital order processing system

The logistics management game’s nerve is the order fulfilment system. The system of the public that starts the logistics activity is offered by customer order. Consumer damage or exorbitant shipping, stocking, and packaging cost, as well as conceivable production damages caused by repeated impact on the production line, can all be traced to the costs and improvement of overall interaction. Hence, supply chain management and corporate management information systems are built on the premise underlying order processing and data systems.

Organizations are reconfiguring their activities to fit the new paradigm of electronic commerce. Therefore, ERP systems, purchasing datasets, warehousing, electronic data interchange (EDI, business to business electronic commerce), and electronic data interchange (EDI, business to business electronic commerce) are all contemporary advancements in green supply chain management.

Smart integrated operations

Implementing Smart Connected Operations motivates the vision to describe what the company should look like with its supply chain and production line. This provides the consumers with a hassle-free and convenient operational structure for managing AI ops, devices, IT operations and field businesses, further ensuring cost efficiency. The SIO is a scalable key that can handle millions of endpoints and unfold new revenues for the company. Connected products by digitalization is an example of engaging customers by serving a seamless user atmosphere with modern advancements in SCM [Supply chain management]

Artificial intelligence

In logistics, artificial intelligence is assisting in the delivery of the powerful optimization skills necessary for more precise production scheduling, improved efficiency, excellent quality, lower prices, and higher voltage, all while nurturing healthy and safe working conditions. However, talking deeper, one of the most challenging things in the supply chain is to maintain the optimum stock levels for avoiding the common ‘stock out issues’. For aiding this, AI and ML formulate to predict future demand of the products based on customers’ needs. When companies become familiar with the forecasted demand and supply through these technologies, their issues of being stocked out ends there.

Blockchain

Nevertheless, in logistics management, the idea is to allow a limited fraction of trusted entities to simply trade among each other while strengthening security, guaranteeing contract performance, and cutting costs. This technology helps to measure distribution networks, supply quantities, shipping documents, and many other items. Not ending here, Blockchain also assists to optimize small business financing by removing unpredictable sources and risk factors, henceforth resulting in full transparency of financial records and speeding up the processing.

You don’t spend on technology, you invest. This is what technology and supply chain merger outcome symbolizes;

- Positive and profitable cash flow

- Best predictive strategies

- Organized channels of Inventory, supply and demand

- Real-time deployment

- Virtual visibility on logistics.

- Owning control over the inventory

- Saving operating costs

- Surpassing the competition

- Improved warehouse efficiency

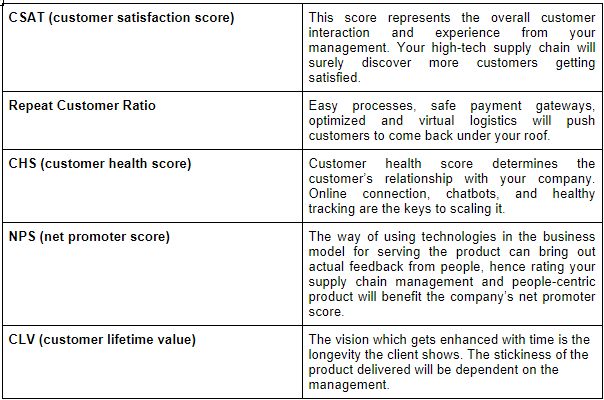

Note that the most efficient supply chain results in customer satisfaction and retention. Once you find your compatible technology, the above-mentioned results don’t look hard to achieve. Let’s talk numbers? The benefits of technology in supply chain management directly affect your company’s certain customer success ratios.

These numerical and practical benefits aided many E-commerce and other businesses in the race.

As a corollary, proper utilization of organizational information systems and technologies that are integral to logistics is the need of an hour. Concluding here “Innovation is the dazzling ball where every solution to our problems exists,” although, at the end of the day, it will have to either address business challenges or equip the organization to pursue a unique chance in the market. ”

“Everything boils down to robustness and the quest of emerging technologies.”

Your patience to read this showed curiosity on how you want to get benefit from technology in your supply chain management. We are here to serve you right; visit our page for matching your needs to grow the business.